In the rich tapestry of Thailand’s cultural and artistic heritage, I found myself immersed in the life of a local craftsman at Bang Sue Lane in Thailand, a carpenter whose hands breathed life into wood, crafting stories in each piece he created.

Understanding the Process

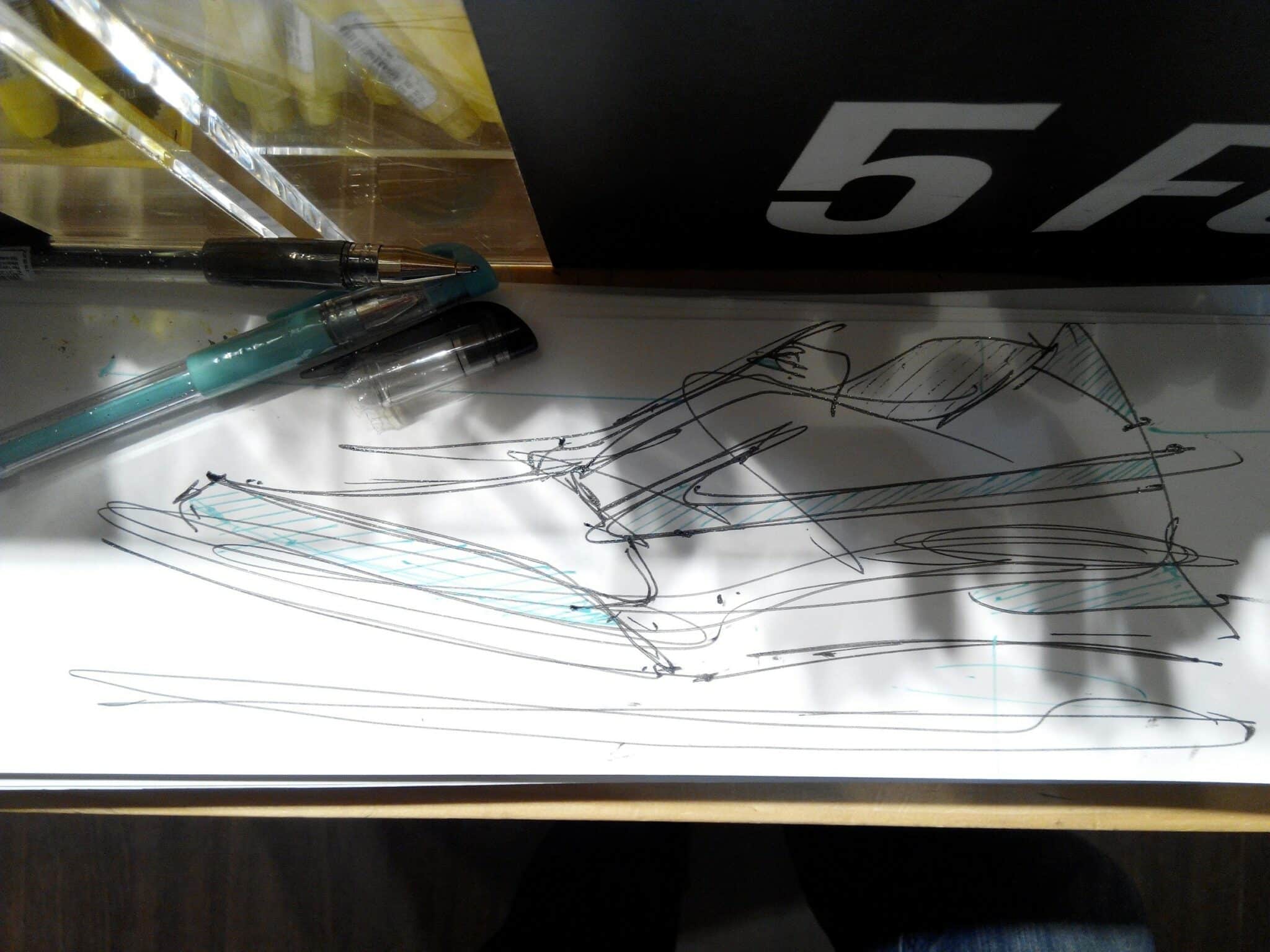

Designing a product involves a delicate balance between creativity and practicality.

Designers, like myself, thrive on innovation and pushing boundaries.

However, without the technical know-how of technicians, these ideas remain abstract.

Technicians are the ones who bring these sketches to life!

This relationship starts with understanding:

- Designers must understand the capabilities of materials and manufacturing processes.

- Technicians must grasp the designer’s vision and intent behind the sketches.

Communication is vital here. A designer’s sketch, while visually appealing, needs to be explained in a way that the technician can understand and execute.

Working Together

While individual skills are essential, the real magic happens when designers and technicians work together:

- Empathy and Respect: Designers respect the technician’s technical knowledge, and technicians value the designer’s creativity. This mutual understanding fosters a collaborative environment where ideas can flourish.

- Problem Solving: When technical challenges arise, the combined expertise of both parties leads to creative solutions. The designer might tweak the sketch, while the technician suggests modifications that align with manufacturing realities.

- Iteration and Refinement: The back-and-forth between designer and technician often results in product refinement. Technicians might suggest changes to make the design more manufacturable, inspiring the designer to enhance their initial concept.

To make any project succeed,

a good relationship with the team is more important than any skill.

Cultivating the Relationship

To foster a strong designer-technician relationship:

- Regular Interaction: Hold regular design reviews where both parties can share feedback. This ensures the design evolves with real-time technical input.

- Education: Designers can benefit from workshops on manufacturing processes, while technicians learn the basics of design principles to better understand the designer’s mindset.

- Respect for Expertise: Acknowledge the expertise of each role. Designers shouldn’t dictate manufacturing processes, and technicians shouldn’t alter the design without understanding its intent.

- Celebrate Success Together: When a product is successfully launched, celebrate this achievement as a team, reinforcing the value of the partnership.

Laser cutting is used by the industry to cut material using laser. The whole process is operated by a computer. To do so, we give to the supplier an .ai file (Native format of Illustrator)

Chit Chat with a carpenter of Bang Sue Road

The carpenters of the lane didn’t speak English well enough for us to converse (and we don’t speak Thai). One directed us to another wood shop nearby – who I believe is a friend, but also competitor.

We met a smiley person who was welcoming and very friendly.

We asked him few questions. He was not the technician himself, so whenever he couldn’t answer well, he asked to his team to feed our curiosity.

I realized passionate people love sharing their passion, their craft to curious people. 🙂

What type of wood do you use?

We use Plywood, also called Rubber wood – as it come from the tree that produce rubber.

What is the maximum thickness of the wood board for the laser cutting?

1.4mm

How much does it cost to use laser cutting?

It depends on the type of work. It doesn’t depend of the size, but the time. Longer it takes for the machine to process, more expensive it will be.

Between laser cutting and laser edge, which one is more expensive?

Laser edging cost more. Even though the laser is not as strong as laser cutting, it covers more surface.

There is burn edges for the laser cutting. How to avoid this?

We can’t avoid them unfortunately. Thicker the wood, stronger the laser will be.

I noticed on a sample that one side was burnt, but the verso was clean.

So I asked him: Can we send you the mirror image of the artwork, so we could get it clean?

Yes of course!

When can you deliver?

It depends. The machine is on site. If you need, we can process now.

As a designer, you can take any inspiration and export it in other domains. For example, laser cutting is commonly used in Fashion industry.

I actually used to proceed with Laser cutting project on leather when I used to work for the shoe industry in China. It was pretty cool to see our artwork become reality on a piece of leather, then applied on a lady shoe.

Somkid, our interlocutor is actually mixed Thai and Chinese. His father is Teochew like me (Chinese minority)- so he could actually speak the dialect. Maybe if he could not speak English we may had this exchange in Teochew. Hehe.

Conclusion

Conclusion of what today inspired me:

Be humble, and get patient. A good working relationship is always better with a smile. 🙂

From sketch to product, the relationship between the designer and technician is what makes ideas come to life. This relationship, built on understanding, respect, and good communication, is what really makes a difference in product design.

It’s not just about a good sketch or knowing how to make things; it’s about how these skills are brought together through teamwork.As someone who has gone from sketching as a kid to designing professionally, I can say that the best things happen when we work together, understanding and helping each other.

This is what makes design truly innovative.

And you, how do you deal with the design or technical team?

Is it more like a tension, competition or a complete harmony ?

Let us know about your experience in the comments!

Cheers,

Chou-Tac

Woowww Chou-Tac

nice one

Merci Renata ! 🙂